The cyclotron at the Texas Center for Proton Therapy in Irving, Texas, is big.

Weighing 220 tons—or as much as a fully loaded Boeing 757—the unit had to be welded to the bottom of the ship that brought it to the Port of Houston from Belgium because if it shifted even slightly during the voyage, it could capsize the boat.

Once on land, the truck transporting the cyclotron from Galveston, Texas, to Irving took three days to make what is normally a four-hour drive, escorted by police officers and using a route dictated by the Texas Department of Transportation because many bridges wouldn’t be able to bear the load.

Why go to all that trouble? The cyclotron, which accelerates protons to two-thirds the speed of light and directs them on tumors with submillimeter accuracy, is a crucial piece to proton therapy. The treatment has fewer side effects than traditional cancer treatments, allowing patients to maintain their quality of life during and after treatments. This makes a significant impact on children, too, whose bodies are most sensitive to the long-term effects of radiation. (For more on the design of cancer care facilities, read here.)

Growth in proton therapy center

In 2001, there was only one proton therapy center in the United States, located at Loma Linda University Medical Center, but that number has since grown to more than 25 proton therapy centers in the U.S. The freestanding Texas Center for Proton Therapy in Irving opened in November 2015 to serve the Dallas-Fort Worth Metroplex.

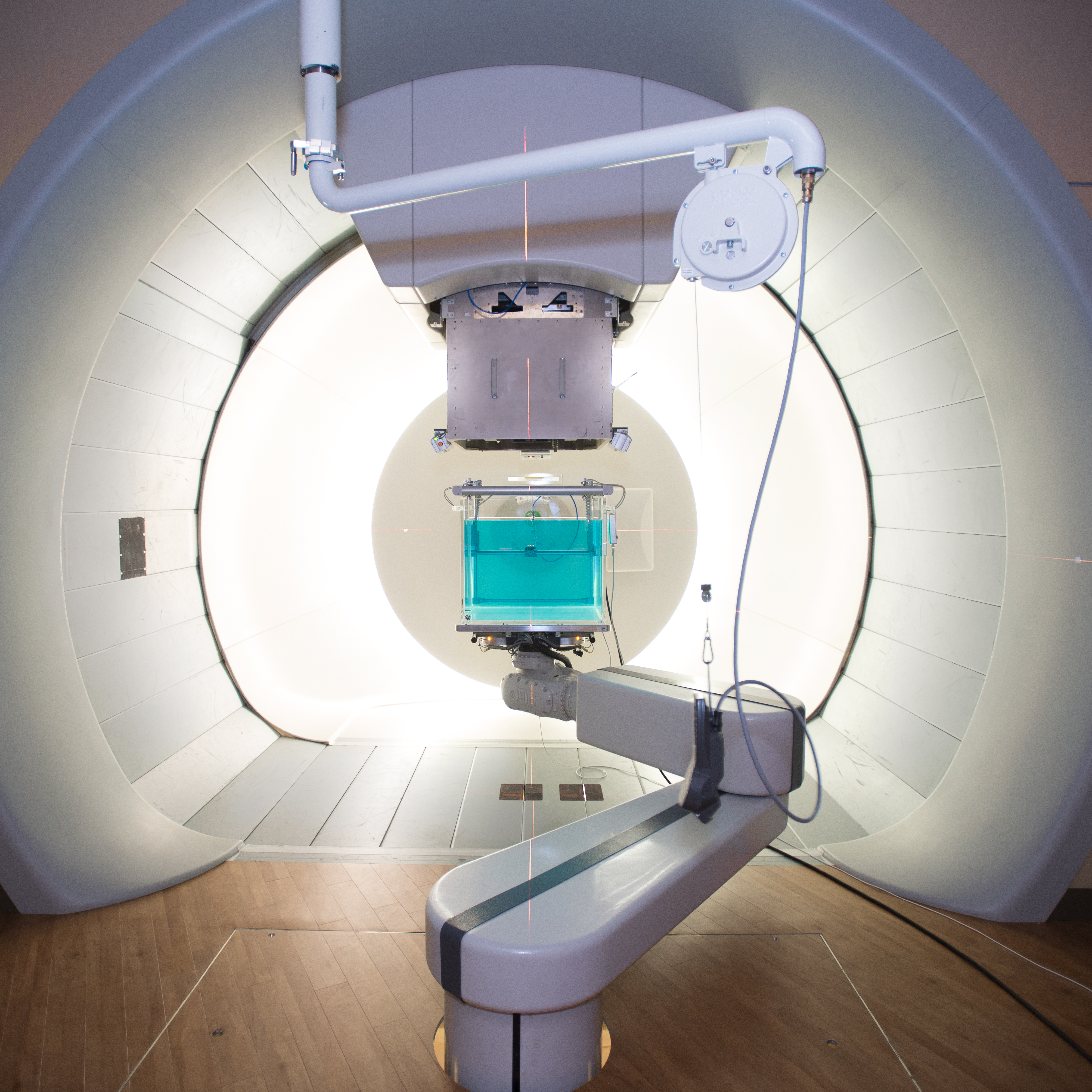

Building a proton therapy facility is just as complicated as getting a cyclotron to one, requiring extraordinary precision in design and construction. For example, at the Texas Center for Proton Therapy, a 143-yard beamline was constructed to transport protons from the cyclotron to three treatment rooms. Two of those rooms house 30-foot tall, 110-ton gantries that can rotate the proton beam 360-degrees to target a tumor from any angle.

Bringing the facility online for Metroplex communities took collaboration, meticulous planning, and a commitment to complete the project without delay.

Design challenges and solutions

Here, we discuss several challenges and the solutions applied on the project, which can yield knowledge for future projects:

Challenge: Transportation and installation—The cyclotron is the mission-critical heart of a proton therapy center. Aside from the challenges of simply getting it to the site, project teams must consider how to get it into the building. The size and weight of the unit makes it almost impossible to be lowered through the roof into a building or moved in through a door.

Solution: The unique aspects of a proton therapy site must be considered early in the process to properly plan for this key piece of equipment. For the Texas Center, the cyclotron was pulled in to the building through a side wall opening using a railroad track-like system. The opening, at nearly 12-feet thick, was later infilled with solid blocks to complete the shielding system requirements.

Challenge: Structural considerations—Concrete walls between 8-12 feet thick are required for the facility to achieve the shielding required to protect patients and staff from radiation. At the same time, the walls need to accommodate extensive cabling for the proton therapy equipment (21 miles for the Texas project).

Solution: By building onsite and installing preassembled components, project teams can save valuable time and hit important deadlines while maintaining the quality control necessary to serve the medical equipment. For the Texas Center project, prefabricated conduit runs and 16,000 cubic yards of concrete in the 19,000-square-foot treatment zone made the difference.

The construction team saved 7-10 days per concrete pour by racking the conduits on the ground. Using prefabricated components helped the team work in a controlled environment and ensure that every conduit was accounted for and allowed the team to make progress on the conduit runs while other team members were installing rebar and preparing to pour concrete.

Challenge: Foundation stability—Seismic and ground considerations must be considered for every project to ensure the facility will have a strong foundation that lasts for years to come. The Texas facility was in an area recently prone to tremors and with troublesome expansive soils that tend to shift.

Solution: Knowing your location and planning accordingly can help project teams address these issues as quickly as possible. In Texas, the team consulted with geo-tech engineers PSI (Arlington Heights, Ill.) and structural engineers Walter P. Moore (Houston) early in the process and mapped out a plan to stabilize the building.

Nearly 300 piers, far above average for a building of similar size, were drilled into bedrock an average of 65 feet deep to prevent the beamline and treatment zones from moving, as well as to ensure stability between the clinical and treatment zones. The team also used void forms to prevent differential settlement and allow soil to shift under the building without disturbing the clinical side.

Challenge: Educating the subcontractor community—Proton therapy centers need to be built with an attention to detail mirroring the precision of its life-saving treatments. Because there are so few proton therapy facilities in the country, few contractors and trade contractors have this expertise.

Solution: The construction team took the time to educate subcontractors and craftspeople on the nuances of this complex project and the critical importance of precision. The team also coordinated early trade contractor involvement with the building interface documents (BID, RFE requirements, MEP coordination, and transportation planning).

The contractors also learned about the physics of radiation and how it affected construction, such as building the rooms to contain stray radiation particles. By creating a collaborative relationship with everyone involved on the Texas Center for Proton Therapy, the project stayed on schedule and the center was able to begin treating patients four months earlier than planned.

As proton therapy centers become more prevalent in the U.S., more builders and construction specialists will need to learn from the experiences of the early adopters. While some challenges will be location-specific, each project team will need to address the challenges of transportation and installation, structural considerations, and educating its workforce to ensure project success.

Sean Ashcroft is a project executive at DPR Construction (Dallas). He can be reached at [email protected]. Gary Barlow is director of Texas Center for Proton Therapy (Irving, Texas). He can be reached at [email protected]. Jay Armand is director for design and construction at McKesson Specialty Health (The Woodlands, Texas). He can be reached at [email protected].